Castings

Castings

TECHNICAL PARAMETERS

The size of castings is limited by following parameters:

| Weight | 0,002 kg – 15,00kg | |

| Minimum wall thickness | 2 mm | |

| Maximum dimensions | lenght | 500 mm |

| width | 250 mm | |

| height | 100 mm | |

| diameter | 240 mm | |

| Standard roughness of the surface | (aftershot blasting) | Ra 6,3µ |

* Requirements close to the mentioned parameters have to be consulted individually

Dimensional accuracy meets standard requirements:

- STN EN ISO 8062-3

- VDG-P 690 /Germany/

- GOST

STEEL CASTINGS

Steel castings are specific with higher content of C, Mn and Si. These elements improve their foundry properties. According to specific standards and customer requirements, it is possible to add aj other elements. Precision castings are suitable for the production of stressed machine parts and are characterized by mechanical properties such as tensibility, solidity, notch toughness, and so on.

The steels from which castings are cast in Zlievareň Zábrež are divided into the following main subgroups:

- carbon /for example STN 11600, 12010, 422643, 422660, 422670, 422819, DIN GS52, 55Si7/

- low alloyed /for example STN 14220, 422830, 422842, 422843, DIN 16MnCr5, 15CrNi6, 42CrMo4/

- medium alloyed /for example STN 17241, 422760, DIN 1.4408/

- highly alloyed /for example STN 422951, DIN 1.4849, 1.4852, 1.4865/

IRON CASTINGS

Their basic feature is that, in addition to carbon, they always contain silicon. It gives them resistance to corrosion and increases their workability

- gray cast iron, whose carbon content exceeds 2.14%. It is characterized by high compressive strength, easy machinability and only slowly corrodes. It is suitable, for example, for the production of low-tension slide bearings. / e.g. GG25 /

- ductile cast iron, which is made from gray cast iron by adding magnesium to the pan before casting. Its advantages are significantly better mechanical properties (for example the tensile strength achieves 900MPa). Elongation and notch toughness also increase. It is particularly suitable for the production of high-tension parts such as crankshafts, connecting rods, pistons etc./e.g. GGG 40/

- white cast iron is characterized by high temper, wear resistance and fragility. It is mainly used for blades and shotblasting equipment parts, where high hardness (over 65HRC) and wear resistance is required. The name originated from the characteristic discoloration of cast iron fracture area. /e.g. Sedur 204/

Bronze castings

All types of copper alloys with different elements (In most cases with copper and tin) except zinc /e.g. CuSn10, CuSn12, CuSn12Ni1/

Brass castings

Alloy, the main ingredient of which is zinc. /e.g. CuZn31MnAl, CuZn36Pb1/

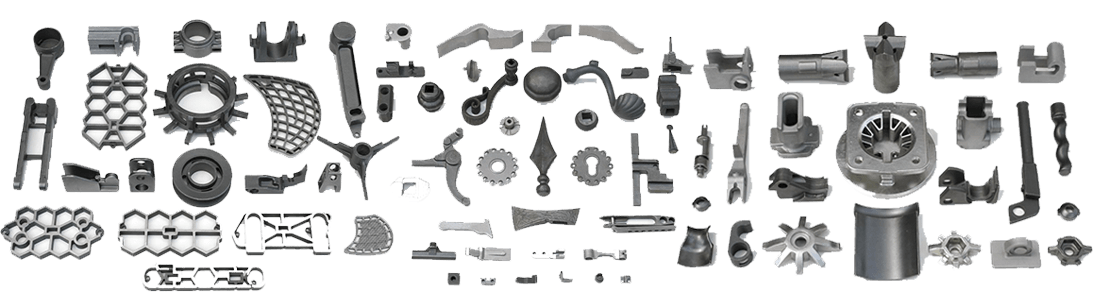

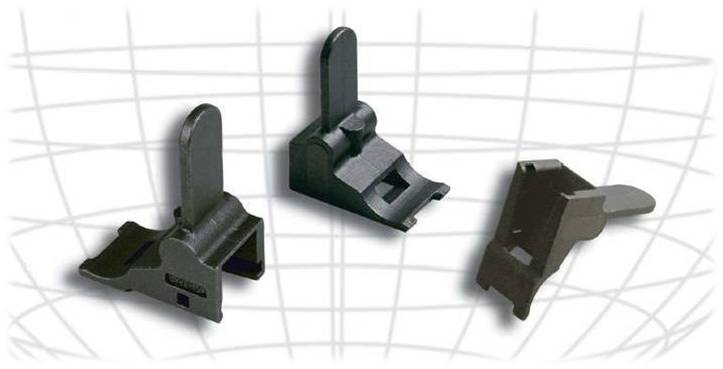

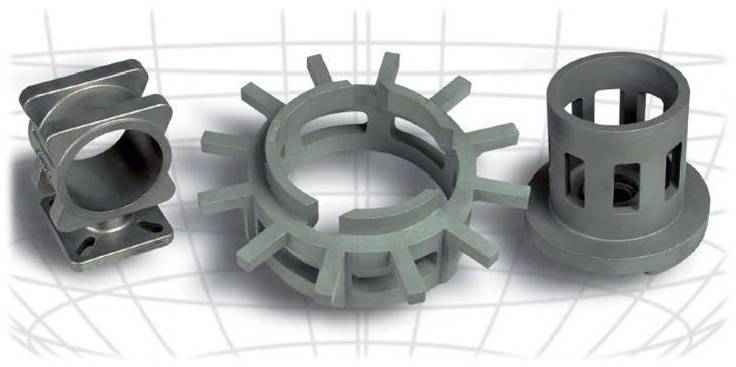

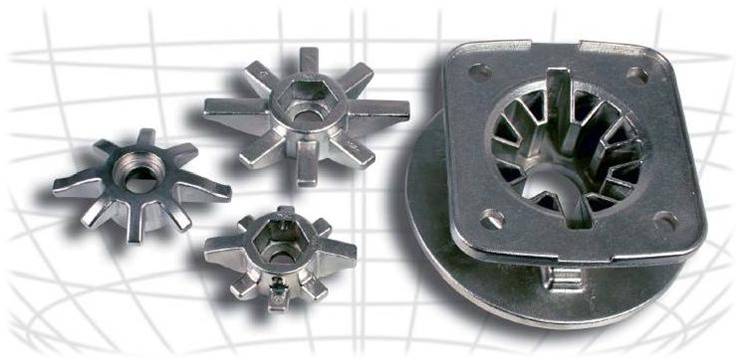

What we produce

Our products – investment castings